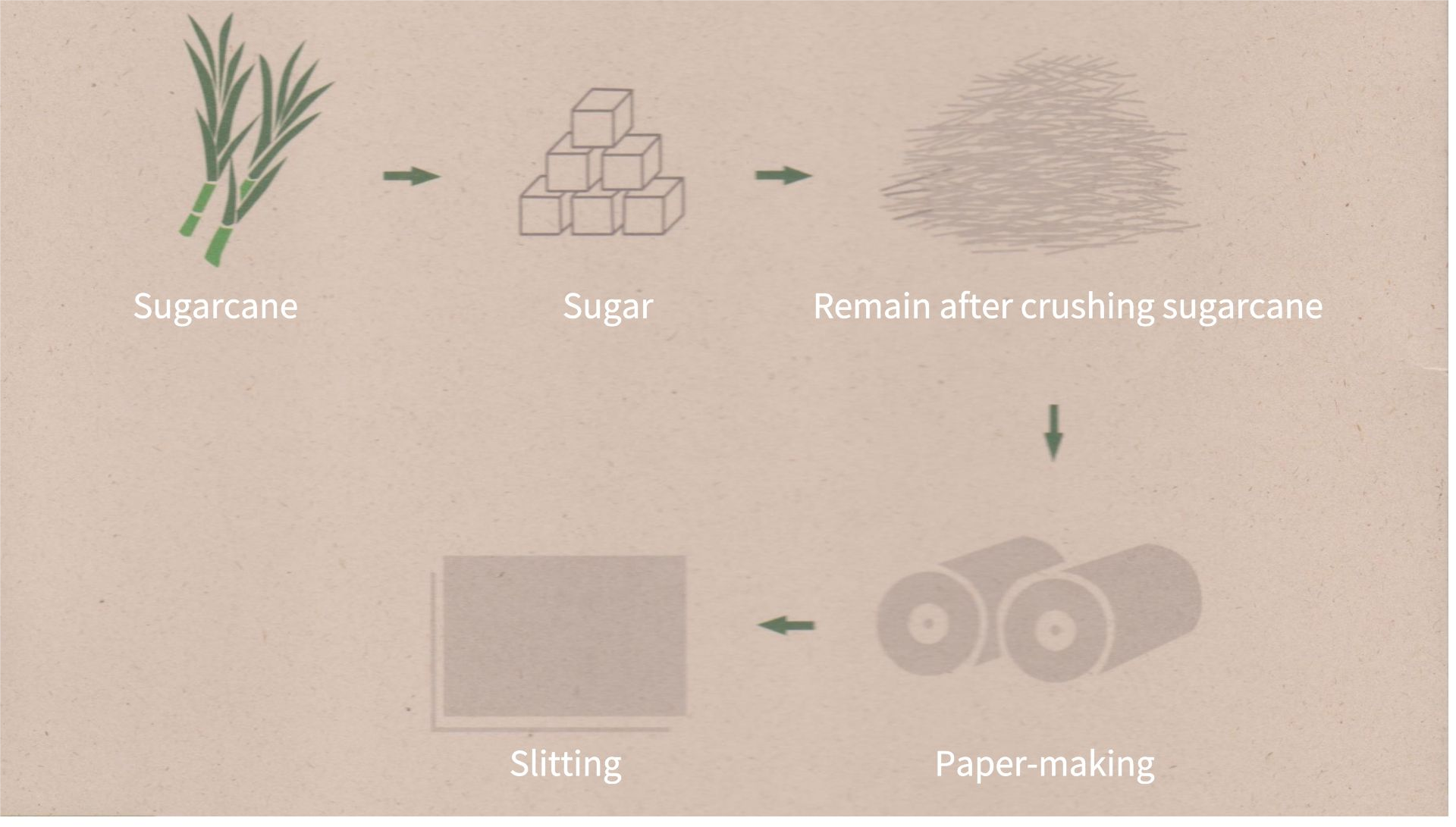

Overview of sugarcane pulp paper

Sugarcane pulp paper is an environmentally friendly composite material made from bagasse and other wastes, which is widely used in books, packaging, kitchenware and other fields. With the concept of environmental protection deeply rooted in people's hearts, sugarcane pulp paper has gradually become a new favorite among printing materials.

Second, the printing performance of sugarcane pulp paper

The printing performance of sugarcane pulp paper is stable, and it is suitable for ordinary printing, letterpress printing and screen printing and other printing methods. In different printing methods, the scope of application of sugarcane pulp paper also varies.

1、Ordinary printing

Ordinary printing is the most common type of printing, using ordinary ink or water-based ink. The printing effect of sugarcane pulp paper in ordinary printing is excellent, with high clarity and bright colors, especially suitable for some cultural prints and sketches.

2、Letterpress Printing

Letterpress printing refers to the printing method in which the part of the desired content on the letterpress plate is raised and ink is applied to the plate so that the printing material prints the desired patterns and words. Sugarcane pulp paper is suitable for letterpress printing, which can effectively retain the lines and details on the page, and at the same time has a good performance for some Chinese characters and simple patterns.

3、Screen Printing

Screen printing refers to making the desired pattern or text on the screen, when printing, ink is poured into the top of the screen, a curved knife scrapes off the excess ink, then the screen is placed on the printing material and printed with a squeegee or a pressure platform. Sugar cane pulp paper also performs consistently in screen printing and has a high degree of toughness in the printed result.

Third, the factors affecting the printing effect of sugarcane pulp paper

Sugarcane pulp paper as a printing material, the printing effect is affected by a variety of factors, mainly including the following aspects:

1, the thickness of the fiber: the thicker the fiber, the more uneven the surface, the worse the printing effect.

2, thickness: the greater the thickness, the better the printing effect.

3, smoothness: the higher the smoothness, the more excellent the printing effect.

By controlling and adjusting these factors, the printing effect of sugarcane pulp paper can be better ensured.

If you interested sugarcane bagasse paper, welcome to contact us.

Post time: Jun-06-2024