Green Packaging Paper - China Factory, Suppliers, Manufacturers

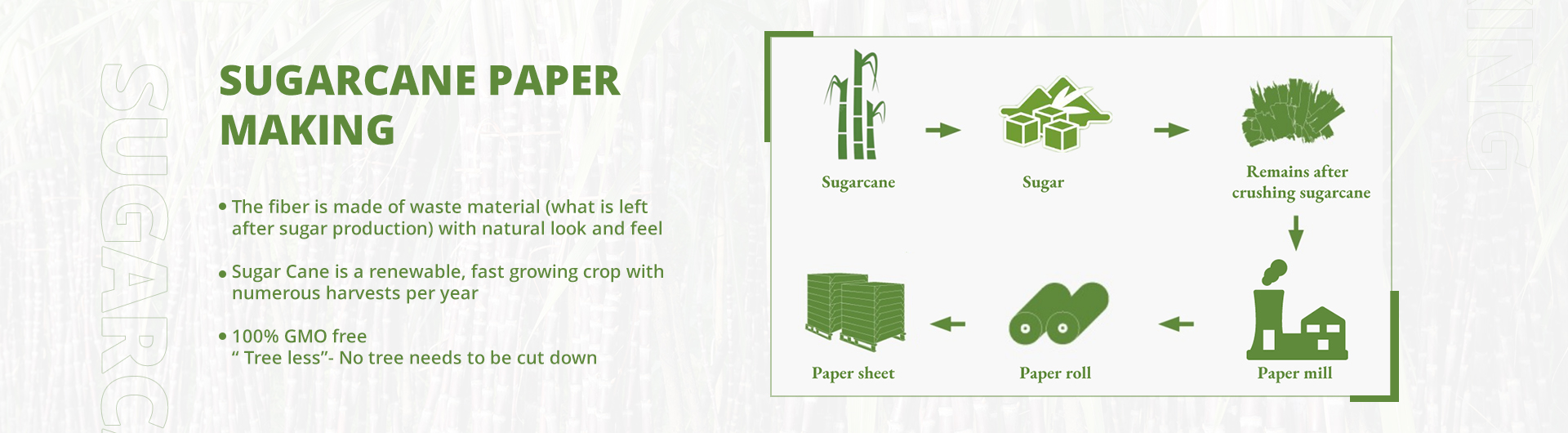

Compared to wood pulp paper, cane pulp paper consumes relatively little energy and water. The production process of sugarcane pulp paper is simpler and consumes less energy, resulting in significant savings in energy resources. At the same time, sugarcane pulp and paper consumes less water in the paper production process, reducing pressure on water resources. Green Packaging Paper, Hamburger Box , Beauty Sustainable Packaging , Eco Friendly Packaging Materials ,Eco Friendly Skin Care Packaging . Environmentally friendly packaging has become an inevitable trend in the development of skin care and beauty product packaging, but also an important bargaining chip for brands to enhance their competitiveness. The new generation of consumers is very sensitive to the concepts of low carbon, environmental protection and reuse, especially the young consumers of Generation Z, who are more concerned about environmental protection and personal health. They are very sensitive to the concepts of carbon, environment and reuse, especially the young consumers of Generation Z, who are more concerned about environmental protection and personal health. As a result, sustainable packaging is no longer just a buzzword or a choice, but is becoming a necessity. The product will supply to all over the world, such as Europe, America, Australia,Ecuador, Venezuela,Luxemburg, Germany.to the use. Two types of paper cups for different uses and processing forms, the quality of the paper cup material requirements are different. Paper cup material in addition to meet the requirements of its packaging and processing performance, but also must have a certain degree of suitability for printing drama, and paper cup printing to meet the paper cup processing and molding of heat sealing conditions1. Hot drink cups.Usually used to hold hot drinks packaging trade, the material used for its processing is the use of PE single-sided composite paper, that is, single-sided laminated paper. Printing is generally done on the non-PE side. Directly printed drama on the paper surface. By the need for dry and hot drinks, the move paper cups need to be processed with a certain degree of thermal insulation, so usually these products require a certain thickness and stiffness of the paper to increase the thermal insulation of the paper cups of the publication of the printing, the larger the volume of the use of paper the thicker.

Related Products